Plastic waste has become a big concern for the country and companies are trying to contribute to solving this issue. With a similar aim, oil-to-telecom major Reliance Industries (RIL) has launched a new project to use plastics in road construction.

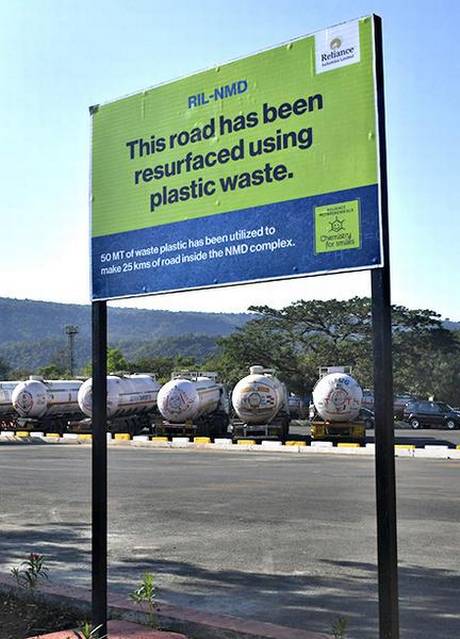

As a part of its sustainability and circularity initiatives, RIL has built a 40-km road network having 50 tonnes of post-consumer plastics as a key ingredient at its Nagothane Manufacturing Division (NMD). The plastics used in this has things such as multi-layer films used for packaging of wafers, snacks, flexible polyethylene packaging materials used by e-commerce companies, garbage bags, cling wraps and other flexible plastic products collected from within the township and surrounding areas of Pen taluka.

Impact of using plastic

The company has done this to create a solution for disposal of non-recyclable post-consumer plastic waste and the use of plastics in the road-mix has improved durability and strength. It has provided superior bonding among aggregates, lower seepage of water, and lesser erosion – all this resulting in reduced abrasion of tyres.

The time and cost

The construction of these roads at NMD began in May 2019 and was completed in just 2 months. The Raigad area was lashed by torrential rains last season. Nagothane alone received a record 2,500 mm rainfall. The cost of a kilometre of a road with plastic — 3.5 m wide, 5 cm topping — costs ₹1 lakh less to make as compared to a conventional bitumin-only road.

What experts say

Talking about this initiative, Vipul Shah, chief operating officer (COO), petrochemicals business, RIL, said

“This is part of RIL’s endeavour to instil sustainability and circularity concepts in everything they do. The roads at Nagothane manufacturing division are a proof of concept that even end-of-life plastics can be utilised in a sustainable manner in creating meaningful and useful assets.”

The company is advising National Highways Authority of India (NHAI) to include plastic mix in its specifications for road projects and will assist road builders in adapting to this technology which will utilise plastic waste to build stronger roads. This can be a game-changing project both for our environment and our roads, Shah added.

Usually, recyclable plastics can be reused nearly 8 times, but it is the single-use plastic— like confectionery wrappers, food bags and straws—that are the immediate cause of plastic pollution. Considering this, RIL said it has started its own, as well as outsourced garbage collection and segregation which enables the collection of sufficient plastic to be shredded to prepare a mixture at its sites.

Considering the benefits of both environment and roads, we can say more such initiatives should be taken by brands to improve the life of people. What are your views on this? Share your thoughts in the comments section.